Robotics team introduces members to engineering, programming

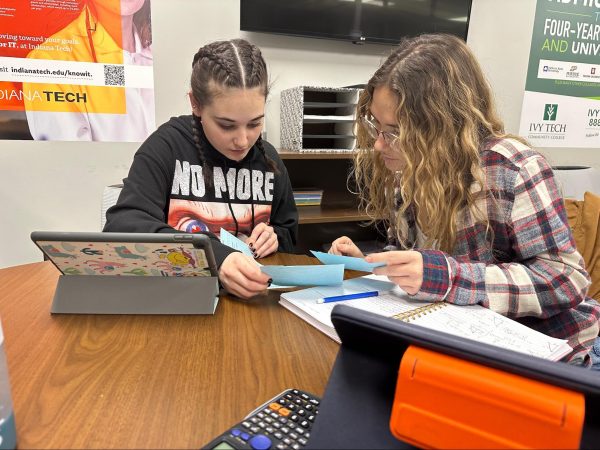

Junior Sidd Chhettry drills a hole into a bar for a demo robot.

October 20, 2021

The Innovation Center is injected with electric energy as mentees and mentors alike fill the air with a harmony of intellectual thoughts and the creaking of machinery, paired with the melody of impactful discussions, comparable to the steady chants of monks in the echoing chamber of a temple. This is the scene at the Innovation Center, home of Team 1741, also known as the Red Alert Robotics.

Red Alert Robotics was created in March of 2005 to aid high school students become the future of engineering and technology because there was no official club to advance science and technology based knowledge amongst their pupils.

“[Robotics] gives me the opportunity to engage with machinery and learn about many aspects of machinery. It also gives us the chance to do graphic design and programming, which are all aspects of STEM,” freshman Eshan Thete, a rookie, said.

The team focuses on the sundry aspects of building a robot, such as designing components for the robot, financing team-related operations, programming robot-related commands and assembling elements of the robots to create the final product.

“We have design and build teams that design and build robots from scratch every year. And we’ve got an operations team that does all of our planning for outreach and all of our business type stuff. So there really is something here for everyone and everyone gets to try everything,” senior Elijah Leser, the executive captain, said.

However, the robotics team doesn’t delve into the competition instantaneously. The team has an offseason that lasts from June to December. During the offseason, the team works on the demo robot, which they introduce to students in order to pique their interest in robotics as well as in numerous charity events.

“[The offseason is] time to design and plan to build a robot for exhibitions. Time to learn and practice important stuff like programming, designing, and machine operating. A time to get to know and connect with the captains, mentors, and other teammates so that when build season comes, you can work together in a team effectively,” Thete said.

Robotics provides an opportunity for students to test new waters and delve deeper into STEM-related sciences that will help them decide on career choices and college subjects.

“Robotics is a great way to get experience before heading into a field as well as to try something out. That way you don’t go to college and spend a bunch of money on a degree that you realize you don’t want,” Leser said. “There’s also college scholarships through FIRST, which is our big league. They offer a ton of scholarships every year that will help pay for college and pay for training to go into a career.”

One of the ways students can get acclimated to robotics is by being part of the design team, who primarily focus on CAD (Computer Aided Design) to help create blueprints and design the robot through the help of an application called Autodesk Inventor 2018.

“At the start of every season we’ll go to a kickoff and they’ll tell us about what the game is for the year,” junior Grant Embrey, the design captain, said. “Then our task is to build a fully functioning robot that meets the requirements of the game in about 8 weeks. Our first step of that is on CAD. [We] model every aspect of our robot on there and then we can use that as essentially blueprints for the manufacturing team as well as assembly.”

However, designing a robot during the competitive and build season compared to designing one during the offseason is very different, and it is important for students to recognize these differences in order to work toward a logical solution.

“Well, in the competitive season we’re on quite the time crunch, and it’s very important that we pay attention to things because CAD can be finicky at times and little mistakes can reverberate throughout. Also, you have to be very aware of how you work on designs collaboratively because there are some intricacies to how you have to do that to make sure there aren’t any mistakes,” Embrey said.

However, the design team isn’t the only team tied to helping the robot function. The SPEC team, which stands for Strategy, Programming, Electronics and Controls, focuses on the programming aspects of the robot.

“Throughout the year we work on putting together a code base for the robot as new parts get designed,” senior Stephen Reeves, the SPEC captain, said. “We will work on different programming designs for those. For electronics, we will work with the more mechanical side of the team to put together a controls board and wire everything correctly. Near competition season time, we work with [the] drive team a lot to see what controls they want on the robot and we’ll also make autonomous [programs], which allows the robot to move without human direction, so it will follow pre-designated directions.”

With that in mind, the SPEC team also has to prepare to escalate the pace of work for the build season, in which students work toward building lines of code specific to the challenge presented at kickoff, rather than editing bugs in old ciphers of code.

“Programming in demo season, a lot of the stuff is just fixing code. Like right now we are working on fixing the code for JAWS, which is an older robot from six or seven years ago. For that we are changing all of the code, which was originally C++, to Java, which is what we run most of our code in. It’s stuff like that and troubleshooting different things. Like, we just worked on troubleshooting some of the driving code for our most recent robot, as well as making different modes for doing demonstrations,” Reeves says. “During the build season, a lot of it is gradually making the code as we get the designs in. Once we know what type of drive train we have, we would throw together the code to have something ready for them to test the drive train, once we get it sufficiently prototyped. We also brainstorm what we want to do for autonomous and different systems we want to learn and generally test the robot as it gets built.”

While the SPEC team works on the digital aspects of the robot, the MATS team, which stands for Machine and Training Safety, works on the more physical and interactive facets of building it.

“MATS stands for Machining and Training Safety. The machining part [of MATS] is using all of the machines that are in the shop like the mill and the band saw and train all of the new rookies about the machines and the safety of it as well. Safety can also be in the shop or general safety things too,” junior member Kyle Upchurch said.

While the MATS team works on introducing safety during the offseason, the work ratchets up during the build and competitive season, during which all knowledge gained during the offseason, like a specialized engineering process, is applied into real-life situations.

“Our engineering process starts at kickoff. At kickoff we see what the game is, so we brainstorm what are our ideas on what we want to do with the game. So, we split into different groups, we CAD it out and see what would work best and then after we test and prototype we’ll make a final CAD. Then we come together, [discuss about how] this fits this in terms of drive train stuff and have it machined out and [built],” Upchurch says.

Not all of Red Alert Robotics focuses on the building of the robot directly; rather, the Operations team, a keystone to the whole organization, channels its attention to fund the features of the robot and the teams related to it.

“Operations in a general, basic setting is everything non-engineering with a little bit of engineering. We do everything from business outreach media, like social media, graphic design, photoshop design, flyers, recruitment, all of that stuff. Everything that gets our team out there and that helps us win any of the awards that do not have to do with engineering. And then we also analyze the robot, we put the sponsors on the robot,” junior Brinna Porat, the operations captain, says. “So we’re doing all of the business stuff and making sure our sponsors are well recognized. [We also participate in] reaching out to people in our community and overall spreading the word of our robot.”

Not only does the Operations team indirectly help the team by spreading the word about the team and helping their community, they strive toward giving students access to the necessary resources to build the robot and provide a more immersive and enhanced environment for the students in the building through raising money for the robot.

“Actually, we are primarily raising money now so that we have money for the competition season because the stuff that we buy is really expensive and we are completely funded by ourselves and we don’t get money from the school except for the grants that we get from the Center Grove Education Foundation and other foundations like that. We sit down and we write a lot of grants at this time. We try to get a lot of money from other places during this time so that we can get new motors and new parts without having to worrying about the price and without engineering have to stress about not having the money to get it,” Porat says. “We start budgeting years ahead to know ‘we have this much money to spend there,’ and we plan grants years ahead so that we have new money to buy laptops for competition season. In competition season, of course we are still writing grants, and we’re still trying to get the supplies but we primarily front load that so that we have the money we need to operate when it comes to that time.”

Despite the well-organized divvying of responsibilities and the help of sponsors like Crossroad Engineers PC, Rolls Royce, Allstate, Indiana State Police and many more, it is important for the group to stay on task and mesh together. The team places special emphasis on inclusivity and safety, which in turn lead to the well-oiled machine that mentors and students alike strive for.

“We really have three main things here. Our first one is Challenge Accepted. It’s about not turning away anyone or not turning away any challenges. To take everything that comes at us and apply ourselves to make it better. The next one is ‘Cool Kids make robots’. That’s really something that we do more for recruiting purposes. It’s that anyone can make robots,” Leser said. “Cool kids can make robots. We’ve got a football player on the team this year. Robotics is cool. It’s something to make [students] feel more confident about themselves. [The] last one is ‘Safety is a Culture’. That influences everything we do. Safety glasses everytime we’re in the shop, close toed shoes, long pants, as well as all of our behavior at competition and towards other teams. Like a couple of years ago, we made battery spill kits for everyone in Indiana.”

Robotics has helped students progress and advance their knowledge on STEM-based fields.

“Robotics has helped me in life by giving me something to do instead of just hanging around,” freshman member Hunter Petkovich said. “I think that robotics has helped me learn more about technology and how things work in robots, and [has] had a positive impact on my life.”